Rigging

Leisure Services

Yacht rigging

Al Saqer marine through its partnership with Marine Tech LLC a company formed in the early 1990’s has been selected to offer support for the products and relationships that Marine tech has successfully delivered to the region since its inception. Al Saqer marine maintains a stock of rigging materials, ropes and yacht spares to facilitate repairs and can consult and guide on maintenance programs and yacht upgrades for all styles of yachts in the GCC region. We pride ourselves in delivering a professional and prompt service, whether it is supplying some new bungee rope to re-rigging your mast, we at al Saqer marine have got your needs covered.

The Standing Rigging (shrouds, forestay, backstay) of your sailboat are critical components and need to be inspected and maintained. Each wire should be checked for loose strands and breaks along the entire length of the wire with specific attention to the end fittings and anywhere it comes in contact with other rigging (ie. spreaders). Each fitting should be inspected for wear and the assembly should be replaced if there is significant wear, stress cracking or if the fitting hole has become oval.

Wire Running

Rigging is also subject to wear and should be inspected often. Wire to Rope halyards are the most common wire running rigging but adjustable forestays, vangs, and backstay systems can also have wire components. The wear normally found on wire running rigging is broken strands at the fittings and along the length (often referred to as meat hooks) of the wire that passes around a sheave. As the wire wears the small broken strands along the length can catch clothing, skin, and sails resulting in small injuries, discomfort, and chafe. Broken or worn strands significantly reduce the strength of the wire and should be replaced.

Al Saqer Marine is outfitted with the equipment and skills to carry out you’re Swaging and Nicro pressing needs for Your wire needs.

Nicro Press Fittings

Are used to put loops or stops in a wire. The two primary fittings are a stop sleeve which fits the diameter of the wire and an oval sleeve that allows two wires through. This is a common fitting found on many dinghies, catamarans, and daysailers. Ideal for lower load applications and very convenient as there are many hand tools available. Al Saqer Marine can nicro press wire from 1/16″ to 3/16″diameter. Or 1.5mm to 4mm if you prefer metric measurements

Machine Swage Fittings

Are compressed on a wire using a Swaging Machine. There are many different fittings available and the mechanical joint between the fitting and the wire is much stronger than a nicro press. This style is found on many boats from dinghies to mega yachts. Ideal for standing rigging but requires a specific tool and is not a do-it-yourself option. Al Saqer Marine can swage wire from 2.5mm to 10mm diameter. For larger jobs AL Saqer Marine can provide a measurement service at your location and have our manufacturer supply the items ready made from the factory. This service allows you to ease your concerns about incorrect measurements and orders and expensive shipping of items if incorrect.

Ordering a new wire

So what do we need to provide you with a new wire made to order. We have created a sheet for you to complete with the required details for us to be able to create and supply to you a new wire for your yacht or dinghy as per your requirements. While we can attend you yacht in person to take measurements and pictures or you could send the item to us this does not always suit requirements so we have created and provided this attached form so that you may share with us some required information and if required we have somewhere to start to ask further information so that we can produce for you your required replacement.

Architectural Rigging

Through its partnership with Marine tech LLC, Al Saqer marine keeps the finest quality Stainless steel 316 materials in-stock for the completion of architectural wire rope systems. We offer quality materials from our suppliers Sta-lok in the UK to deliver architectural design solutions for everything from balustrade, flag poles to shade structures. We offer 1×19, 7×7, 7×19. All wires up to 10mm diameter can be made to order here in the UAE and for larger diameter wires we offer a personalised measurement, supply and fitting service. Our team can work around your facilities working hours to minimise disruptions.

The wire elements and fittings used in your architectural wire rope systems whether they are balustrade or shade structures need to be inspected and maintained. Each wire should be checked for loose strands and breaks along the entire length of the wire with specific attention to the end fittings and anywhere it comes in contact with other metals or rub points. Each fitting should be inspected for wear and the assembly should be replaced if there is significant wear, stress cracking or if the fitting hole has become oval.

Al Saqer marine can offer you an inspection service and quote for any observed issues.

We offer a design and supply service also for New Requirements.

Mooring ropes and Rope supply services

Al Saqer Marine through its partnership with Marine Tech LLC can offer rope from the Well-known Brand ROBLINE ropes manufactured by Teufelberger. They offer custom made, performance, cruising, single braids, dinghy and sports boats ropes, tapered lines, moorings and anchor lines.

Al Saqer Marine keeps a varying array or lines in stock for the majority of Boats from dinghies up to yachts on the 50ft range.

We can offer bespoke splicing services for your ropes and mooring line needs and can supply specialised requirements at well-priced commercial rates.

Swaging and Nicro Pressing

Al Saqer Marine can perform either Nicro Pressing or Machine Swaging on most types of rigging wire. Unfortunately, our swaging machine is not capable of working with rod rigging and we do not sell ‘hand swage’ fittings.

Measuring Your Existing Wire

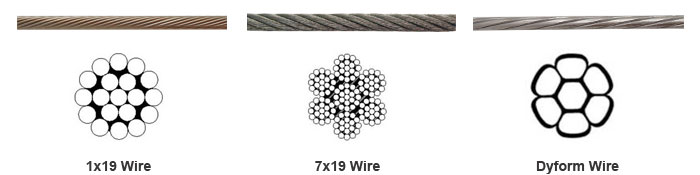

Wire Type: Most sailboats use standard 1×19 stainless steel wire but some performance dinghies, sportsboats, and catamarans have Dyform shrouds or forestays. Running rigging is usually either 7×7 or 7×19 construction as it is more flexible and runs around sheaves.

Thread Direction: Threaded ends are either left or right handed. A right hand thread is the standard thread found on commonly available bolts but in the case of rigging turnbuckles the two threaded ends have to be opposite threads for the turnbuckle adjuster to work properly.

Length of Wire: Al Saqer Marine uses the effective length of the wire for measurement also known as bearing point to bearing point. This method of measurement uses the point of contact or load at each end of the wire. In the case of an eye or toggle this is the outer edge of the hole.